There are various types of wood flooring manufacturers around the country, but only a select number are member mills of the Maple Flooring Manufacturer’s Association (MFMA).

There are various types of wood flooring manufacturers around the country, but only a select number are member mills of the Maple Flooring Manufacturer’s Association (MFMA).

Does it really matter if your sports floor comes from an MFMA mill or not? If you care about quality, accuracy and consistency, it certainly does.

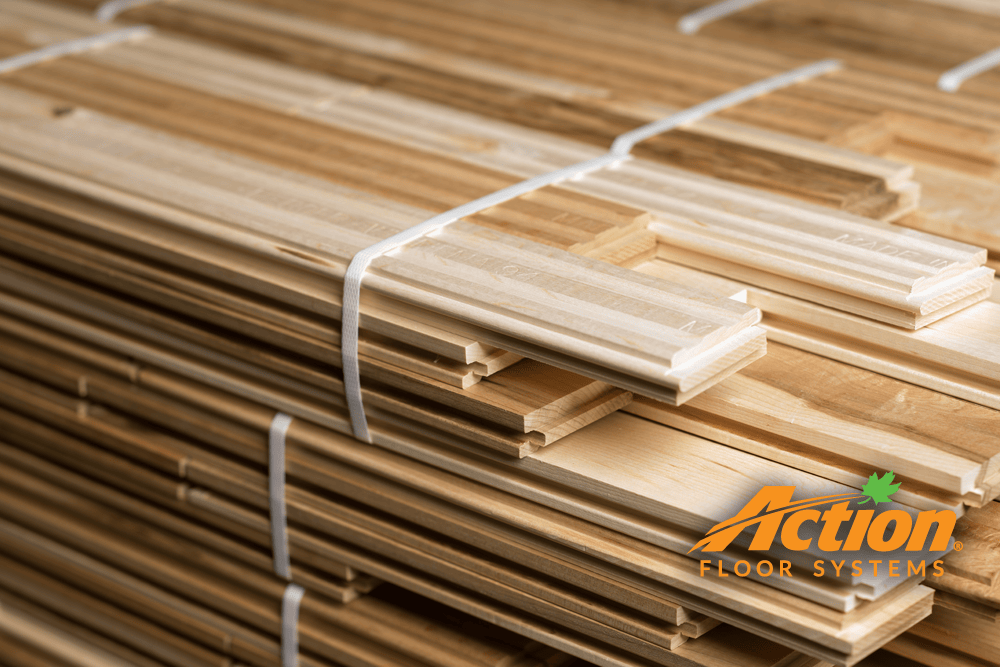

Action Floor Systems® is honored to be one of just six MFMA member mills producing premium hardwood sports flooring. Our vice president of sales and marketing, Ron Fenhaus, explains what makes this affiliation so important. He says it all starts with the type of maple we use.

“To be an MFMA member mill, you can only manufacture flooring with northern hardwood maple, and it needs to be harvested north of the 30th parallel,” says Fenhaus.

That is why, as you may notice, all MFMA mills are located in the upper Midwest. The reason for such a specific geographic region is because of the winter conditions northern hardwood maple endures.

“Long winters in the North mean a much shorter growing cycle compared to southern species of maple,” says Fenhaus. “So, the growth rings within northern hard maple are tighter together. That makes for a much denser, more resilient material.”

How MFMA Grading Rules and Inspections Work

While Action Floors starts with high quality maple, the commitment to producing a premium product doesn’t end there. The MFMA lays out explicit rules regarding board length, moisture content, aesthetics of the maple and many other criteria concerning the manufacturing process and the quality of the wood flooring.

Each MFMA member mill is subject to random, unannounced inspections to assure the association’s guidelines are being followed. These inspections can occur three or four times per year. Fenhaus says it is an arduous inspection that leaves no stone (or board) unturned.

“The inspector has the right to go into the warehouse and select material that was already run and palletized, and they can inspect material that’s currently being run on the floor,” he says.

“MFMA mills typically have no issues following the association’s guidelines for the aesthetics of grading hardwood maple. The inspections tend to focus on milling quality and board length. Those are the aspects that are more likely to be discovered in an inspection.”

As the MFMA states on its website:

“Some non-MFMA maple manufacturers claim their product matches up to MFMA maple in appearance, but remember that appearance is only skin deep — it’s what’s behind the product that counts. Development and consistent enforcement of strict manufacturing, grading, packaging, shipping and installation standards are key to providing a quality product. The MFMA trademark is your assurance that these standards have been met.”

Learn more about the standards Action Floors adheres to when you review the MFMA’s Detailed Grading Specifications.

Daily Quality Assurance at Action Floors

Being held to high standards reinforces Action Floors’ commitment to quality control. When the MFMA shows up for a surprise inspection at our mill in Mercer, Wisconsin, there are no concerns. As our plant manager Karl Anderson explains, that’s because we are monitoring quality from the time the lumber comes through the gate until a floor system is shipped.

Anderson says there are three primary areas of focus for quality assurance in the Action Floors mill: moisture control, milling accuracy and the grading process.

1. Moisture Control

“Moisture control is crucial,” Anderson explains. “If we don’t get that part right from the start, nothing else we do matters. The wrong moisture content can cause the product to be dimensionally unstable.”

Trained experts begin measuring for moisture as soon as the green lumber comes in. We continue to measure as it goes through kiln drying. That includes both digital and manual measurements.

“Even though a computer program runs the kiln, our kiln operator is old-school,” Anderson says. “He will physically cut samples and measure moisture to double check what the computer is telling us.”

That system of checks and balance remains throughout the milling process. The millworkers running the flooring machines conduct spot checks every hour. If the moisture level is wrong, we can remove that product and re-dry the lumber.

Finally, moisture is checked one last time before shipment. That level is documented and sent along with the load.

2. Milling Accuracy

While most of our millworkers are cross-trained to perform a variety of duties, it’s a different story for our flooring machine operators. For this crucial role, we employ dedicated experts who are responsible for setup, operation and calibration of the machines.

Anderson says the flooring machine operators check the instruments used for calibration and document the results daily. The operators also cross check each other, and mill supervisors provide an additional set of eyes for even more quality control.

Supervisors are continuously providing feedback to flooring machine operators and others throughout the mill. Ongoing training and collaboration support our System for Success, ensuring we maintain the quality and precision expected of us.

Anderson says Action Floors empowers its millworkers to support quality control by allowing all employees to call attention to possible issues.

“Anyone can stop the production line at any time if they notice a problem, which is the quickest way to get everyone’s attention” he says. “Everyone has the freedom to ask questions and seek clarification on whether something is a defect.”

3. The Grading Process

Identification of the correct grade for the hardwood maple occurs after milling. Action Floors employs around two dozen people who are trained to follow the MFMA’s grading guidelines.

As lumber loads come through the mill, the grade of lumber changes. That’s why we have staff closely watching the product. At any given time, up to eight people are working the grading line.

Boards are closely inspected. In some cases, grading staff will pull a board that may be half second grade maple and half third grade. That board can be cut and sorted into the correct category. This ensures the facilities receiving our floor systems get a product with a consistent look.

As a reminder, all grades of maple have the same structural integrity. They are separated by their natural variations with first grade maple being the lightest and third grade being the darkest.

Choose Quality Hardwood Sports Flooring You Can Count On

When you work with Action Floors, you know you are choosing a sports flooring manufacturer you can trust to deliver a superior product. For Action Floors, our commitment to quality is more than just words. We live by the commitment every day.

“There are a lot of mills that say their quality is just as good as the product from an MFMA member mill,” says Fenhaus. “But these mills aren’t required to live by the same rules as Action Floors.”

Following MFMA guidelines is far from the only thing Action Floors does to provide quality assurance. Check out our selection of hardwood maple sports floors and you’ll notice they go through vigorous performance testing. Plus, we’re also committed to sustainability including support of responsible forestry management.

Action Floors provides options to meet the project specifications and budgets for everything from major arenas to school gymnasiums. Visit our Architects Resource page for details on specific sports floor systems, or contact us with your questions today.